Raycus has developed the QCW fiber laser series, spanning from 75W to 1500W, offering higher electro-optical conversion efficiency, improved optical quality, and reduced maintenance costs. These lasers serve as excellent replacements for traditional light-pumped YAG lasers and are well-suited for industrial applications like spot welding, seam welding, and boring. They provide wide pulses and high peak output power, making them compatible with most YAG systems through simple modifications. Raycus boasts several innovative R&D teams capable of meeting diverse customer demands, offering specialized customization services. Currently, these lasers use QBH connectors, offer output power rates between 10-100%, achieve electro-optical conversion efficiencies exceeding 25%, and support modulation frequencies up to 5kHz. These features make them versatile and highly acclaimed in the market.

The RFL-QCW150/1500, RFL-QCW300/3000, RFL-QCW450/4500, and RFL-QCW600/6000 lasers from the QCW fiber laser series serve as excellent alternatives to traditional light-pumped YAG lasers. They are particularly well-suited for spot welding, seam welding, boring, and other industrial applications that demand wide pulses and high peak output power. These lasers offer compatibility with most YAG systems with straightforward transformations.

- RFL-QCW150/1500

Raycus 150W QCW fiber laser is a perfect alternative of existing light-pumped YAG laser and is an ideal choice for spot welding, seam welding, and other industrial applications.

- RFL-QCW300/3000

This QCW fiber laser product is a perfect alternative of existing light-pumped YAG laser and is an ideal choice for spot welding, seam welding, boring and other industrial applications.

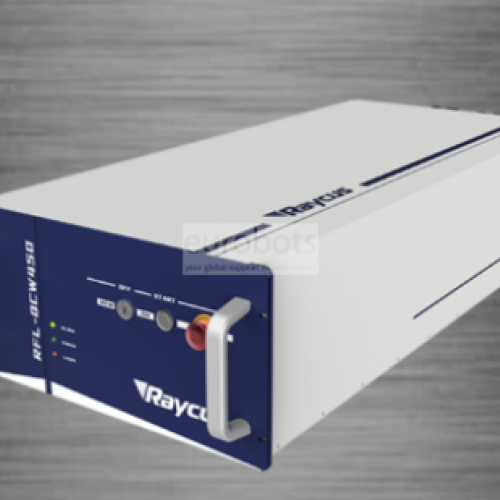

- RFL-QCW450/4500

This QCW fiber laser product is a perfect alternative of existing light-pumped YAG laser and is an ideal choice for spot welding, seam welding, boring and other industrial applications.

- RFL-QCW600/6000

- RFL-QCW1000/3000

- RFL-QCW1500/15000

- RFL-QCW2000/6000

Anwendungen

Fotos

Diagramme